Spat availability

Hatcheries

|

Updates on SRO hatchery runs are published every second month in the oyster newsletter, however spat availability can change quickly and unexpectedly.

|

Wild-caught spat directory

|

Many oyster farmers in NSW rely on the wild-catch of spat. While some farmers catch their own and grow out to market size, others buy in juvenile oysters from wild-caught spat suppliers. The Directory linked here provides a list of NSW wild-caught spat suppliers - to update or add your details to this directory, please contact Laura Stoltenberg ([email protected] or 0488656366).

|

Introduction to nurseries for hatchery produced oyster spat

This information is an introductory guideline for farmers interested in operating field nurseries for ongrowing of small (0.75 mm - 1 mm) ex-hatchery oyster spat. It is not intended nor should be used as a manual.

Spat supply from the hatchery

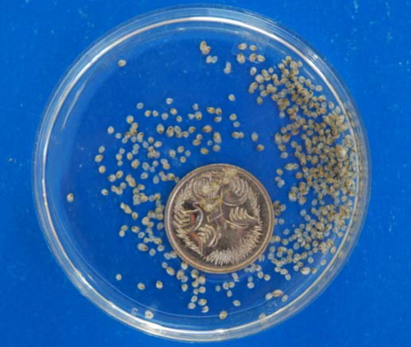

Irrespective of the species of oyster (Sydney rock, Pacific or flat), the larvae are about 330 - 350 microns (1000 microns = 1 mm) in shell length when they settle and transform into spat (juveniles). Newly settled spat (Figure 1) are usually held in the hatchery for a week or more until they are large enough to be retained on a 500 or 1000 micron sieve.

Apparatus

Upweller nurseries of the type illustrated in Figures 2 & 3, are one way that these spat are on-grown to a size at which they are suitable for estuarine growout techniques. The name upweller is derived from a system in which spat are held on a screen in a tank or trough. Seawater is pumped into each tank, which then “wells up” through the screen before passing to waste through a screened outlet into the sump. The example pictured (Figure 3), is a twin tank system with a central overflow sump. There are variations on this design including floating upweller systems or FLUPSYS. Upweller screens can be made from plastic, wood or fibreglass. The example (Figure 2), is the most common in NSW and is made from sheet plastic that is welded in to a 45 cm diameter cylinder. Fine mesh is glued to the base of the cylinder and then secured with an additional ring of plastic that is heat–shrunk around the rim of the screen. An outlet (sleeve) is glued or welded through the upper wall of the screen. This sleeve serves to bayonet mount the screen to the inner wall of the tank connecting it to the sump. A small (1.5 cm) hole in the wall of the screen, opposite the outlet, is used to hold a rod or peg that braces the screen (Figure 2). Plastic mesh secured with a cable tie or similar is placed over the outlet as a back-up screen to prevent spat being accidentally flushed from the screen.Upweller tanks can be constructed from fiberglass, plywood, barrels or moulded plastic and are designed to hold single or multiple screens depending on the water flow that can be delivered to this type of system. The example (Figure 3) is 2.7 m long x 1.25 m wide x 0.5 m deep, with a central trough or channel 12 cm wide. This tank holds 10 screens. Flow rates of water through the screens are an important consideration and vary in accordance with the numbers of spat held, the size of the spat and the amount of suitable food in the water. It is impossible to predict in advance what will be required, however, as a rule of thumb we allow 20 L/minute for each 45 cm upweller screen. Flows however should not be strong enough to lift the spat off the screen into the water column as they will clog the outlet and cause the screen to overflow. Click here for commercial upweller systems.

Stocking upweller screens

Stocking densities for the screens vary with the size of the spat. Spat from the hatchery are usually large enough to be retained on at least a 500 micron mesh sieve, however, for safety these spat are placed on a] 350 micron screen in the nursery. This is done in case the shell of spat is abraded during grading and transport to the field nursery. It is common to stock about 250,000 spat (120 ml) on each 350 micron screen. The spat remain on the 350 micron screen until they are large enough to be retained on 670 micron mesh, at which time they are moved to 500 micron screen. When the spat are large enough to be retained on 1.25 mm mesh, they are moved to 1 mm screen. As the spat grow the number of spat on each screen is reduced. Each 10-screen upweller unit described is capable of handling batches of 750,000 to 1 million spat at a time. But this allows for differences in growth rates within each batch of spat and requires that spat are progressively removed from the system when they reach a size at which they can be transferred to the leases. This transfer is usually not attempted until the spat are at least large enough to be retained on 3-4 mm mesh and will be dependent on the type of nursery equipment used for estuarine growout. Growth is the best indicator of a good nursery and, given suitable water temperatures, the volume of newly stocked spat should increase steadily. Another rough rule of thumb is that the volume of spat should double every 7 to 10 days. If growth is slow or inconsistent, the general health of the spat should be checked and consideration should be given to either increasing the flow rates to screens or spreading the spat into additional screens at the same flow rate per screen.

Maintenance

Upwellers require regular maintenance, particularly when 350 and 500 micron screens are in use as they are very fine and clog easily. Generally, the tanks are drained and the spat are rinsed twice daily with freshwater to remove any faeces, silt and debris. Spat also require regular grading to keep the size of spat on each screen as uniform as possible. Grading is achieved by gently wet sieving the spat through different sized screens. The frequency with which grading takes place will be a function of the rate at which they are growing but generally occurs once every one to two weeks. Grading is also an ideal time to record the volumes of spat within the screens. This is done by placing the spat into measuring cylinders with some seawater and gently tapping the cylinder until the spat settle down to a steady packed volume. The volume is recorded and provides both an indication of the growth since their last volume measurement as well as allowing the nursery operator to make an estimate of the numbers of spat.

Estuary growout nursery

Spat can also be grown directly on the lease using fine mesh bag inserts. For example, spat can be placed into 1 mm Allied Filter Fabric mesh bags that are inserted into Hexcyl longline baskets for lease-based grow-out. Careful consideration needs to be given to where spat baskets are deployed (see the following section). Spat baskets need to be in a convenient and secure area where they can be frequently checked and rinsed to prevent the fine mesh from clogging with silt and debris. Spat should be regularly graded through the estuary growout nursery phase so that they can be placed into mesh baskets with larger apertures (3-12 mm) as soon as possible to promote growth. Nursery baskets & fine mesh inserts suited to these baskets can be ordered through Hexcyl. Smallest mesh insert is 700µm mesh. For more information watch this demonstration here. Fine mesh inserts for Hexcyl and Seapa baskets can also be order through Allied Filter Fabrics.

Selecting a nursery site

There are no guarantees for a good nursery site, but when deciding on a site some questions to consider are:

- In your experience as an oyster farmer would you choose this site to grow small spat?

- Does the site have the necessary infrastructure (power and water)?

- You may have to visit the site twice a day, every day. Is the site readily accessible and will it be comfortable to work there in all weather conditions?

- Is the site prone to high levels of silt or frequently prone to freshwater inundation?

- If prone to freshwater inundation is it sufficiently deep and stratified to reliably access deeper, higher salinity water during such occasions?

- Is the site suitably secure?

- Spat growth is highly temperature dependent. Warmer sites will extend the season over which the nursery can operate.

- Is the site exposed to frequent wind and wave action?

Technical assistance

Should you require any technical assistance or advice regarding the handling or on-growing of hatchery spat, please do not hesitate to contact one of the following DPI staff:

• Dr Wayne O’Connor (02) 4916 3906

• Dr Mike Dove (02) 4916 3807

There are now several well-run nurseries in NSW, we strongly recommend visiting a nursery near you to see the systems first hand, discuss their operation and appreciate what is involved.

• Dr Wayne O’Connor (02) 4916 3906

• Dr Mike Dove (02) 4916 3807

There are now several well-run nurseries in NSW, we strongly recommend visiting a nursery near you to see the systems first hand, discuss their operation and appreciate what is involved.